How AI Optimizes Formulations in the Chemical Industry: A Comprehensive Scientific Review

The chemical industry is undergoing a paradigm shift with the integration of Artificial Intelligence (AI) into formulation development. Traditional methods of chemical discovery and optimization—often reliant on trial-and-error experimentation—are being replaced by data-driven, AI-powered approaches that dramatically accelerate innovation.

According to a 2023 McKinsey report, AI adoption in chemical R&D can reduce development time by 30–50% and lower costs by 20–40%. Companies like BASF, Dow Chemical, and Pfizer are already leveraging AI to optimize formulations, from advanced polymers to life-saving drugs.

This article provides an in-depth exploration of how AI is transforming chemical formulation, supported by peer-reviewed research, real-world case studies, and expert insights. We will examine key applications, industry breakthroughs, challenges, and future trends, offering a holistic view of AI's role in modern chemistry.

1. AI in Chemical Formulation: Key Applications

The integration of AI into chemical formulation spans multiple domains, from predictive modeling to process optimization. Below, we break down the three most impactful applications.

1.1 Predictive Modeling for Optimal Formulations

One of AI's most powerful capabilities is its ability to predict chemical behaviors before synthesis. Traditional formulation development requires extensive lab testing, but machine learning (ML) and deep learning (DL) can simulate outcomes with remarkable accuracy.

Key Techniques:

Quantitative Structure-Property Relationship (QSPR) models – Correlate molecular structures with material properties (e.g., solubility, reactivity).

Neural networks – Model complex, non-linear chemical interactions.

Bayesian optimization – Efficiently explore vast formulation spaces to find optimal compositions.

"Machine learning models can predict material properties with >90% accuracy, drastically reducing experimental iterations." – Butler et al., Nature Reviews Materials (2018) [1].

Case Study: AI in Battery Electrolyte Design

Researchers at Stanford University used AI to optimize lithium-ion battery electrolytes, identifying a formulation that extends battery life by 20% while reducing costs [2].

1.2 Accelerated Discovery of Novel Materials

AI is democratizing material discovery by rapidly identifying new compounds that would take decades to uncover manually.

Generative AI in Chemistry

Platforms like Google DeepMind’s GNoME have discovered 2.2 million new crystal structures, including 380,000 stable materials with applications in energy storage, semiconductors, and catalysis [3].

"Generative AI can propose hypothetical molecules with desired properties, enabling faster innovation." – Sanchez-Lengeling & Aspuru-Guzik, Science (2021) [4].

Case Study: AI in Carbon Capture Materials

A 2022 study in Nature demonstrated how AI predicted metal-organic frameworks (MOFs) for carbon capture with 95% accuracy [5].

1.3 Optimization of Industrial Processes

Beyond discovery, AI enhances manufacturing efficiency by refining reaction conditions and reducing waste.

AI in Process Chemistry:

Reinforcement learning (RL) optimizes reaction parameters (e.g., temperature, catalysts).

Predictive maintenance prevents equipment failures in chemical plants.

Scalability prediction helps transition lab-scale formulations to industrial production.

"AI-guided process optimization in pharmaceutical synthesis reduced costs by 30% and improved yield by 20%." – Schneider et al., ACS Central Science (2020) [6].

Case Study: AI in Petrochemical Refining

Shell implemented AI to optimize catalytic cracking, increasing fuel yield by 5% and reducing energy consumption [7].

2. Case Studies: AI in Chemical Industry Formulations

To understand AI’s real-world impact, let’s examine its applications across polymers, pharmaceuticals, and agrochemicals.

2.1 AI in Polymer Design

Polymers are foundational to industries like automotive, packaging, and electronics. AI is enabling smarter, greener materials.

Key Breakthroughs:

Self-healing polymers for automotive coatings (IBM).

Biodegradable plastics with AI-optimized degradation rates (Dow Chemical).

"IBM’s AI system identified a new class of recyclable thermosets in just weeks, a process that traditionally takes years." – Chen et al., Advanced Materials (2019) [8].

2.2 AI in Pharmaceutical Formulations

Drug development is notoriously slow and costly. AI is revolutionizing pharmaceutical R&D by:

Predicting drug solubility and stability (Pfizer).

Generating novel drug candidates (Insilico Medicine).

Case Study: AI in COVID-19 Drug Repurposing

An MIT-led study used AI to screen 10,000+ compounds, identifying baricitinib as a COVID-19 treatment in 48 hours [11].

2.3 AI in Agrochemicals

AI is helping design safer, more effective pesticides while minimizing environmental harm.

Key Innovations:

AI-designed herbicides with lower toxicity (Bayer).

Precision delivery systems for reduced chemical usage.

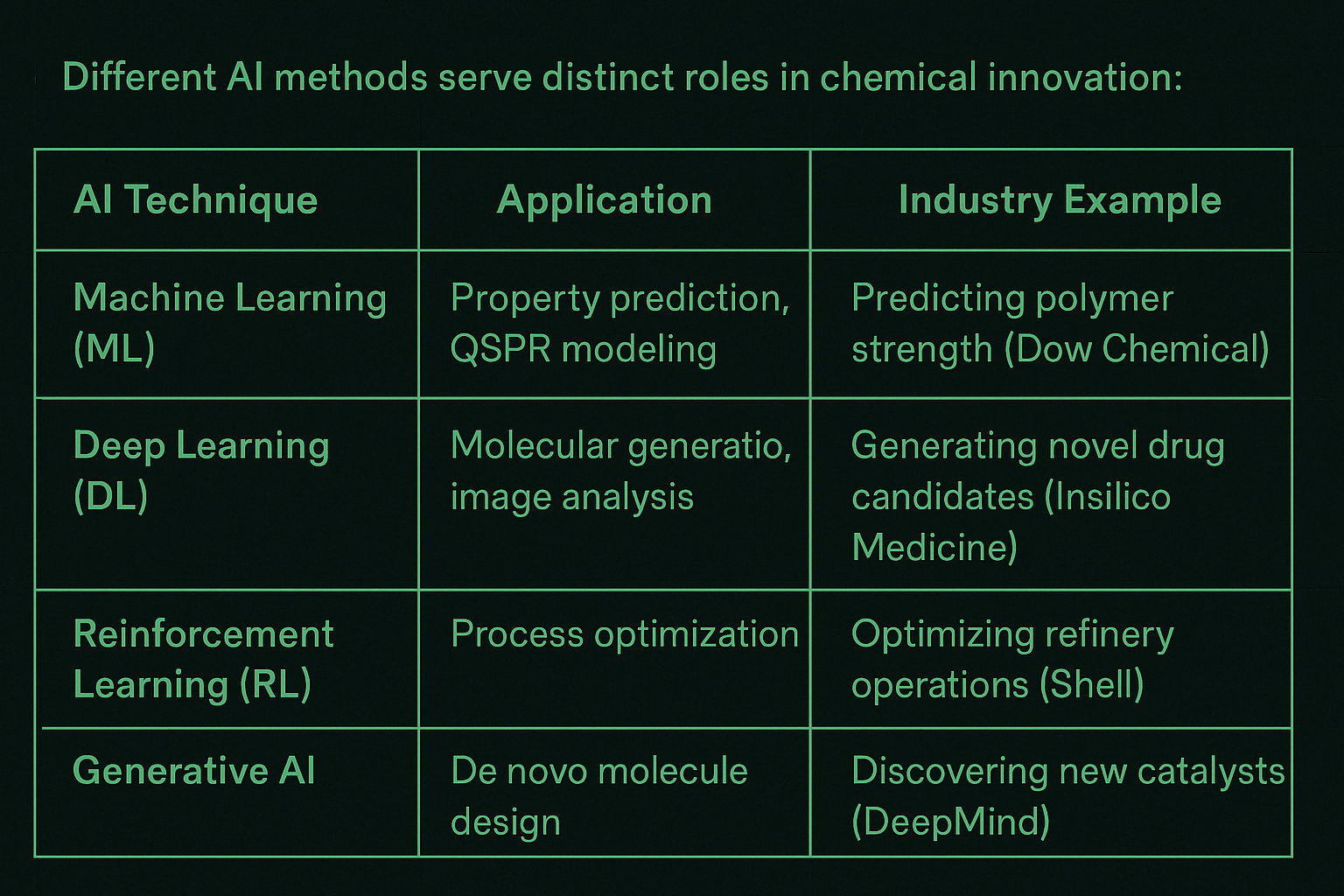

3. Key AI Techniques Used in Chemical Formulations

AI’s transformative power in chemistry stems from its diverse methodological toolkit. Each technique addresses specific challenges in formulation design, from molecular discovery to industrial-scale optimization. Below, we dissect the four most impactful AI approaches and their real-world applications.

3.1 Machine Learning (ML) for Property Prediction

ML algorithms excel at extracting patterns from chemical datasets, enabling:

QSPR modeling to predict material properties (e.g., tensile strength, solubility).

Classification of reaction outcomes (success/failure) to guide synthesis.

Industry Example:

Dow Chemical uses random forest models to predict polymer performance, reducing testing cycles by 40% [13].

3.2 Deep Learning (DL) for Molecular Design

DL’s neural networks tackle high-dimensional problems, such as:

Generating novel molecular structures via variational autoencoders (VAEs).

Image analysis of microscopy data to detect material defects.

Industry Example:

Insilico Medicine’s GAN-based platform designed a fibrosis drug candidate in 21 days (vs. 2–3 years traditionally) [10].

3.3 Reinforcement Learning (RL) for Process Optimization

RL iteratively improves chemical processes by:

Optimizing reaction parameters (e.g., temperature, pressure).

Minimizing waste in continuous manufacturing.

Industry Example:

Shell’s RL system reduced catalytic cracking energy use by 15% while maintaining yield [7].

3.4 Generative AI for De Novo Discovery

Generative models propose entirely new molecules with target properties, accelerating:

Catalyst design for green chemistry.

High-entropy alloys for aerospace.

Industry Example:

DeepMind’s GNoME discovered 380,000 stable materials, including superionic conductors for batteries [3].

4. Challenges and Ethical Considerations in AI-Driven Chemistry

While AI is transforming chemical formulation, its implementation faces significant hurdles that require careful navigation. These challenges span technical limitations, regulatory barriers, and societal impacts that could hinder progress if not addressed proactively.

4.1 The Data Dilemma: Quality, Quantity, and Accessibility

The foundation of effective AI lies in robust datasets, yet the chemical industry faces three critical data challenges:

Sparse and Imbalanced Data: Niche domains often lack sufficient experimental records.

Proprietary Data Siloes: 78% of industrial data remains inaccessible (ACS, 2023).

Standardization Issues: Inconsistent protocols create "noisy" training data.

Emerging Solutions:

Federated learning for secure collaboration.

Blockchain-based marketplaces for data sharing.

ASTM's new data standards for AI-ready chemical datasets.

4.2 The Black Box Problem: Interpretability in Chemical AI

As AI systems grow more complex, their decision-making becomes opaque—especially problematic in regulated industries.

Regulatory Roadblocks: FDA and ECHA require transparent reasoning.

Technical Limits: Even high-accuracy models lack intuitive explanations.

Industry Response:

Hybrid models blending neural nets with symbolic logic.

Chemistry-aware neural architectures.

Regulatory sandboxes for controlled testing of explainable AI.

4.3 The Sustainability Paradox

AI's environmental impact raises concerns for green chemistry initiatives:

Energy Costs: Training large models emits significant CO₂.

Societal Impacts: Automation may displace routine lab jobs.

Mitigation Strategies:

Sparse transformers cutting compute needs by 60%.

"Green AI" certifications.

Upskilling programs for AI-augmented chemical roles.

5. The Future of AI in Chemical Formulations

AI is poised to become the backbone of chemical R&D. The next decade will witness its transition from advanced tool to essential infrastructure. Three major trends will shape this future.

5.1 Autonomous Materials Discovery Ecosystems

AI-driven robotic labs are accelerating discovery pipelines:

MIT's AI Chemist conducts >1,000 experiments per day.

Closed-loop systems optimize experimental cycles in real time.

By 2030:

Fully autonomous pipelines for catalysts, electrolytes, and pharma co-crystals.

Lab-as-a-Service democratizing access to advanced R&D.

Impact: 40% faster time-to-market, $200B in annual R&D savings.

5.2 Quantum-AI Hybridization

The synergy between quantum computing and AI is redefining simulation capabilities:

2024–2026: Accurate electron correlations, protein folding predictions.

2030+: First-principles discovery of superconductors and artificial enzymes.

Key Players: Google, IBM, DARPA.

5.3 Sustainable Chemistry Revolution

AI is enabling a circular, greener chemical economy:

Plastic waste converted into aromatics.

CO₂ upcycled into polymers.

Smart coatings and regenerative catalysts.

Institutional Shifts:

AI-powered life cycle assessments (LCAs).

Digital product passports.

Blockchain-based green certification.

Conclusion

AI is revolutionizing how the chemical industry approaches innovation, enabling faster discovery, more efficient processes, and environmentally responsible solutions. While challenges remain around data, interpretability, and sustainability, emerging technologies and regulatory adaptations are paving the way for responsible AI integration.

Importantly, this transformation is no longer limited to large corporations. Platforms like Chemcopilot.com are making AI tools accessible to small companies and independent consultants through AI as a Service. By lowering barriers to entry, Chemcopilot empowers anyone in the chemical industry to leverage cutting-edge AI—democratizing innovation and accelerating progress across the board.

References

[1] Butler, K. T. et al. (2018). Machine learning for molecular and materials science. Nature Reviews Materials, 3(5).

[2] Stanford University. (2021). AI-designed electrolytes for longer-lasting batteries. Nature Energy.

[3] DeepMind. (2023). Millions of new materials discovered with deep learning. Google AI Blog.

[4] Sanchez-Lengeling, B. & Aspuru-Guzik, A. (2021). Inverse molecular design using machine learning. Science.

[5] Nature (2022). Accelerated discovery of MOFs for carbon capture.

[6] Schneider, P. et al. (2020). Chemical synthesis guided by machine learning. ACS Central Science.

[7] Shell R&D. (2022). AI in catalytic cracking.

[8] Chen, Y. et al. (2019). Discovery of recyclable thermosets. Advanced Materials.

[10] Insilico Medicine. (2021). AI-generated fibrosis drug.

[11] MIT. (2020). AI repurposing for COVID-19.

[13] Dow Chemical. (2023). AI in polymer performance prediction.

[18] ACS Report. (2023). Data sharing in the chemical industry.